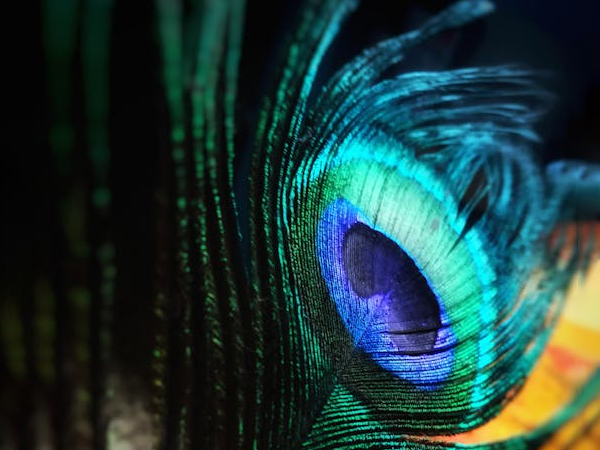

Thin film structure color is based on the multi-beam interference effect of the layered structure of micro and nano optical thin films to achieve unique color changes. The beautiful colors of soap bubbles, butterfly wings, bird feathers and fish scales in nature are produced by nano-scale microstructure through light interference, diffraction and other ways to produce different degrees of reflection, absorption and transmission of the specific wavelength of incident light. The film structure is composed of a variety of metal and dielectric materials with different optical constants, and the thickness and ratio of each film layer are precisely controlled by physical vapor deposition method, which is formed by successively deposited on the same carrier. Under the condition that the viewing Angle changes, the transmitted or reflected light beam changes with the Angle, resulting in the shift of the reflected or transmitted spectrum, which makes the optical film show different colors.

This color rendering depends on the microphysical structure of the film, also known as physical color, without any pigment powder added. Thin-film structural color manufacturing has the advantages of environmental protection of raw materials, environmental protection of manufacturing process, easy mass production, high color saturation of materials, high brightness, wide color control range, structure does not fade, magnetic field response discoloration and so on. Different from the traditional pearl chameleon, the optically color-changing film material has no mica substrate and is all composed of nanoscale film materials. The complex multi-layer film interference structure can achieve richer color change effect, higher color saturation and brightness than the pearl chameleon. Its unique gradient color, Angle color and metal color provide new design inspiration and unique aesthetic perspective for color presentation.

.jpg)

.jpg)

.jpg)